What is the Average Weight for a Live Broiler Chicken?

On average, a live broiler chicken in the U.S. weighs about 6.5 lb (2.94 kg) at the time of slaughter, though the figure can vary, typically anywhere from 6 lb to 7 lb, depending on the year and data source.

Keep in mind: this number is an average. A bird’s weight at slaughter can be influenced by several factors, including breed, nutrition, environment, and market demands. We’ll dive into those later.

Average Broiler Weight Change Over Time

Thanks to improvements in genetics, nutrition, and farming methods, today’s broilers are dramatically different from those of the past. Let’s walk through how broiler chickens have grown bigger and faster over the decades, according to the National Chicken Council.

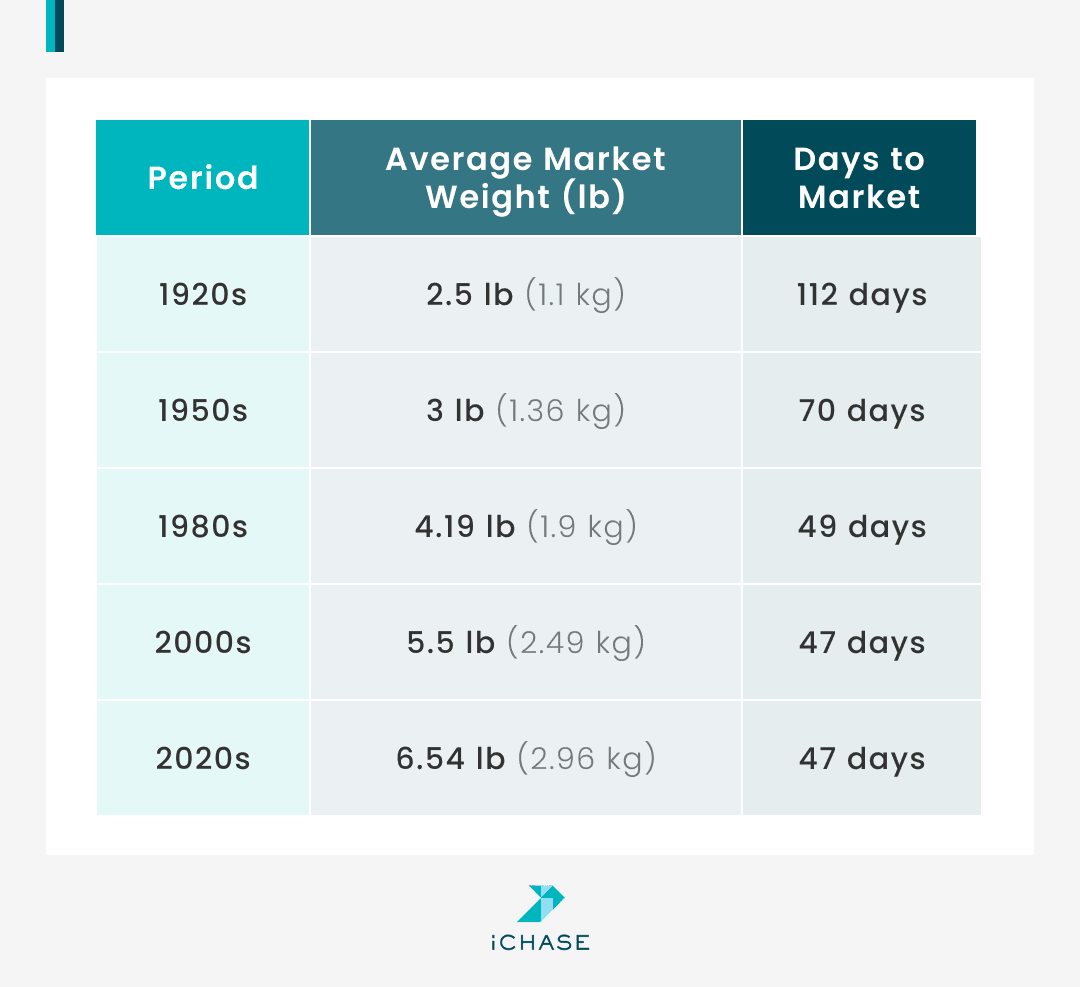

1920s–1950s: Slow-Growing Chicks

In the early 20th century, raising broilers was a slow process. In the 1920s, it could take about 112 days for a bird to reach only 2.5 lb (1.1 kg). Even by the 1950s, growth was still relatively modest, with average weights around 3 lb (1.36 kg) and a market age of about 70 days. Chickens were leaner, smaller, and required much more time and feed to reach a saleable size compared to today.

1980s: Explosive Growth

Fast forward to the mid-1980s, and those same birds hit around 4.19 lb (1.9 kg) in just 49 days. That’s a leap of over a pound in extra weight in three weeks' less time. These gains weren’t just in size; they were also in growth efficiency.

1990s–2020s: Modern Broilers

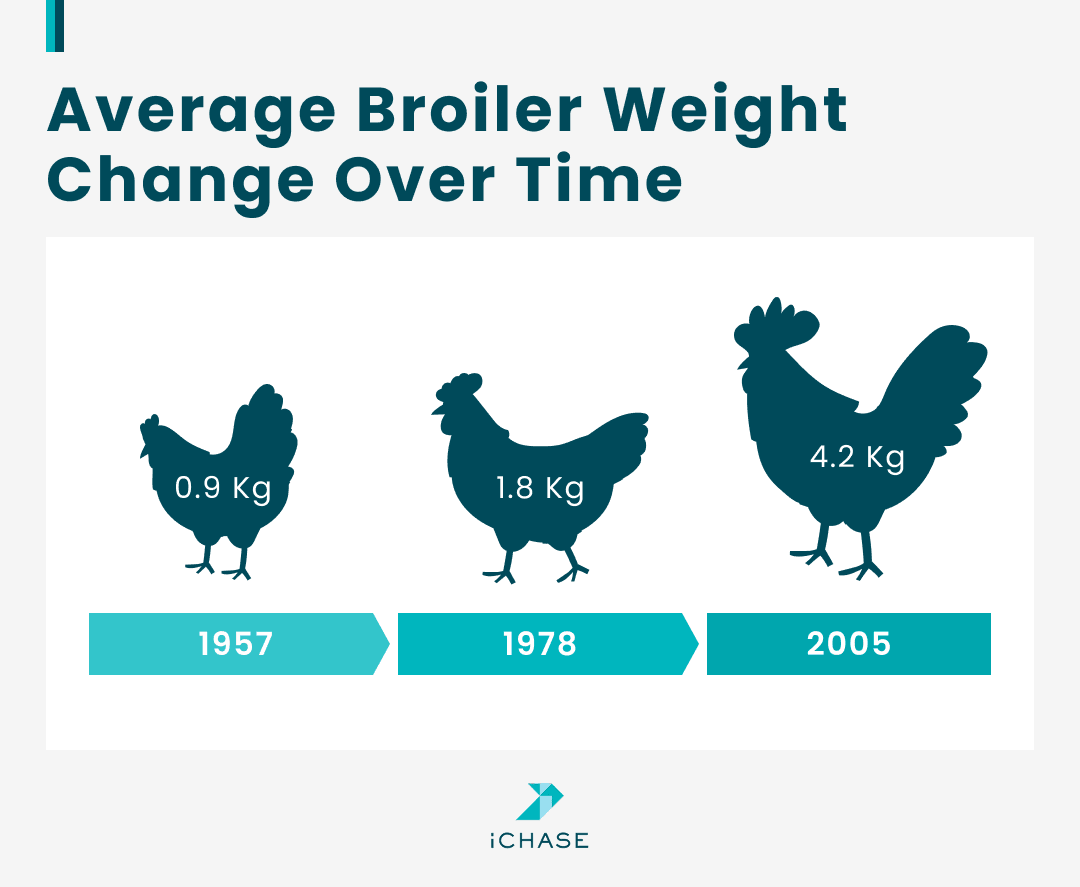

By the 2000s, farmers were seeing broilers reach around 5.5 lb (2.49 kg) in just 47 days, with the lowest mortality rates recorded around that time. Between 1957 and 2005, broiler growth skyrocketed more than fourfold, and feed-to-meat efficiency improved by nearly 50%. Put simply, farmers got far more meat in significantly less time, and at a lower cost.

Now in the 2020s, the trend continues: broilers average about 6.54 lb (2.96 kg) at market, still achieved in 47 days. This showcases the broiler industry’s remarkable strides in breeding, nutrition, and management to grow even larger birds at record speed.

What Factors May Influence the Broiler Average Weight?

The average weight of a broiler chicken may sound straightforward, but in reality, it depends on several key factors. From genetics to broiler management, each element plays a role in how heavy a bird will be at market time. Let’s break them down one by one.

Breed

Selective breeding has improved overall growth, feed conversion, and meat yield in modern broilers. This transformation was no accident. It began in the 1940s with initiatives like the “Chicken of Tomorrow” contest, which encouraged breeders to develop meatier, more efficient birds.

The results led to the rise of commercial hybrids such as the Cornish–Rock cross, which later evolved into powerhouse breeds like Cobb 500 and Ross 308. For instance, Ross 308 can reach 5 lb (~2.3 kg) in around 35 days, while Cobb 500 hits around 4.4 lb (~2 kg ) by 33 days.

Nutrition Programs

Feed is the driving force behind broiler growth. Birds need a well-balanced diet with the right mix of protein, energy, vitamins, and minerals. As broilers mature, farmers typically shift from starter to grower to finisher diets to match their nutritional needs. High-quality feed and constant access to clean water are essential for efficient weight gain. Using a growth chart to track progress helps farmers adjust feeding programs in time, ensuring birds stay on track toward their market weight.

Environment

A carefully managed environment is key to steady broiler growth. A meta-analysis comparing strains such as Cobb and Ross showed that breed performance is strongly influenced by factors like temperature and ventilation. This highlights that even top genetic lines require proper environmental management to thrive.

Well-designed housing with good airflow, lighting, and temperature control reduces stress, encourages consistent feeding, and supports healthy growth. Stocking density is also critical, since overcrowding leads to feed competition and slower weight gain.

Market Demands

Interestingly, consumer demand also influences average broiler weight. Retailers and foodservice companies may request different sizes, as smaller birds for whole-roast markets or larger birds for deboning and further processing. Farmers adjust production cycles to meet these demands.

Tracking Precision

Finally, the way broiler weight is measured makes a big difference. If tracking is inaccurate or done too rarely, it can cause serious issues. Changes in season, poor chick quality, or extreme weather may all affect weight readings and make them unreliable. When this happens, farmers may misjudge flock health, miss the early signs of disease, or harvest at the wrong time. These mistakes often lead to lower weights and lost profits.

That’s why having precise, up-to-date weight data is so important. With the right tools, farmers can make better decisions and keep their flocks on track. In the next part, we’ll look at the common methods used to measure broiler weight.

How to Measure the Correct Average Broiler Weight

The most common way farmers used to record broiler weight was simple hand weighing. You catch a few birds, place them on a scale, and then calculate the average. While this method works, it takes a lot of time and labor. It also stresses the chickens since they have to be handled, and usually, you only get a snapshot every few days instead of frequent updates.

Today, many farms are switching to automatic control sensors and smart weighing scales. These systems track weight in real time, sometimes every hour, without you needing to catch or handle the birds. The benefits are huge: less labor, less stress on the chickens, and far more accurate data. Automatic monitoring can even help detect problems early. For example, sick birds usually lose weight first, so drops in average weight can signal disease before you see other symptoms.

Automated systems don’t just save time; they also help manage flock uniformity. In larger poultry houses, weight data can show differences from one side of the shed to the other. Farmers can then adjust ventilation, temperature, or feed distribution to keep growth more even across the flock. This kind of precision simply isn’t possible with hand weighing.

Benefits of Having an Accurate Average Broiler Weight

For Growers

Accurate broiler weight tracking brings major advantages to everyday farmers. First, it helps improve the out-of-window rate by keeping bird weights within the most profitable sales range. This not only boosts income but also reduces the risk of penalties from slaughterhouses, which often fine for birds that fall outside their required weight brackets.

By monitoring precise data such as feed intake and water consumption, growers can quickly spot changes in growth or health conditions, reducing costly misjudgments and improving overall flock performance.

For Integrators

For integrators, accurate weight data translates into greater efficiency across the entire supply chain. It allows harvest plans to be optimized, with feed formulations adjusted in real time according to the needs of each farm. Logistic costs and overtime are also reduced, since shipments can be scheduled more precisely.

In many cases, reaching target weights earlier means flocks can be harvested sooner, saving days of feed expenses. At the same time, controlling weight within the desired sales window maximizes slaughterhouse efficiency, ensuring birds consistently meet the ideal processing weight for the best returns.

iCHASE Offers You the Smart Broiler Chicken Weighing Scale System

InsightScale is an AI-powered broiler chicken weighing system that uses AccuVision smart imaging to deliver instant, highly accurate weight data, without being affected by seasonal changes. With up to 98% accuracy, flexible connectivity, and a quick setup design, it takes the guesswork out of weight monitoring and makes flock management easier than ever.

InsightScale focuses on collecting precise, real-time weight data inside the poultry house. This information is then processed through InsightYield, our AI analysis platform, which turns raw numbers into actionable insights. Together, they create a complete solution:

- Accurate weighing anytime: AI ensures reliable results regardless of weather or season.

- Automatic data sharing: Weight data is gathered on the farm and sent directly to integrators.

- Harvest plan optimization: InsightYield analyzes the data so integrators can fine-tune feed programs and plan harvests more efficiently.

- Real-time insights: Integrators get a live overview of grower performance and flock health.

- Weight forecasting: Predict future flock weights and even estimate slaughterhouse capacity ahead of time.

Whether you manage a small farm or a large operation, we help you optimize feeding, cut costs, and hit market weights with confidence. Contact us today and discover how we can transform the way you monitor broiler growth!